GAS REDUCTION

CCC NATURAL GAS CHROMIUM IP DIRECT REDUCTION IN A SOLID STATE

The impact of CCC new Canadian patented process on possible future direct reduction of chromite processing, has the potential for global energy reductions equivalent to the effect of completely eliminating energy demand from a country the size of Italy.

CCC CEO Frank Smeenk said “We believe the direct reduction method can be combined with exceptionally low-cost Canadian energy to potentially provide this very large chromite discovery with tremendous production cost advantages. The method will also be improved by the further research work recently completed under the Chromite Research Project of Natural Resources Canada’s CANMET Mining laboratories. The award of this Patent will enable us to now vigorously pursue an opportunity to further develop the process with pilot plant testing in one of the strategic locales that have been under consideration.”

This new natural gas CHROMIUM IP, low temperature, ‘solid state’ reduction process, could have enormous global competitive advantages in terms of reduced capital cost, reduced operating cost, and reduced greenhouse gas emissions.

The potential for CCC’s Chromium IP process to completely revolutionize the world’s ferrochrome industry should not be underestimated. Its impact reaches far beyond exploitation of a regional natural resource.

The Canadian patent on the refining method yields a ferrochrome alloy (by reduction in solid-state without melting, in a reaction with natural gas).

In addition to benefits of the new reduction process itself, test work performed on Ring of Fire ores confirm that the Ring of Fire ores are generally more reducible, resulting in a 15-20% increase in unit capacity, compared to currently processed ores in other parts of the world.

Further, the chromium-iron alloy pellet product produced, can form part of the charge of conventional SAF furnaces producing ferro chrome, as batch or continuously charged components of the steel making process.

Our confidential laboratory test results show that smelters purchasing the metallised product would obtain a smelter capacity increase of 50% without any additional capital expenditure, reducing their effective capital cost from $1200 per annual ton to $800.

This dictates that a very substantial premium to the charge-chrome price may be commanded by this ferrochrome, which may also be readily purified to even higher-value ultra low-carbon ferrochrome, by argon-oxygen decarburization (AOD).

The opportunity to partner in piloting and commercializing CCC’s proprietary gas-reduction process can thus be exchanged for off-take terms with selected steel makers and AOD operators in China, Japan, Korea, and India, as they will all wish to participate in the advantages of highest purity, lowest cost and lowest emissions.

THE TORSTEIN ABSTRACT: LOWER CAPITAL COSTS & REDUCED OPERATING COSTS

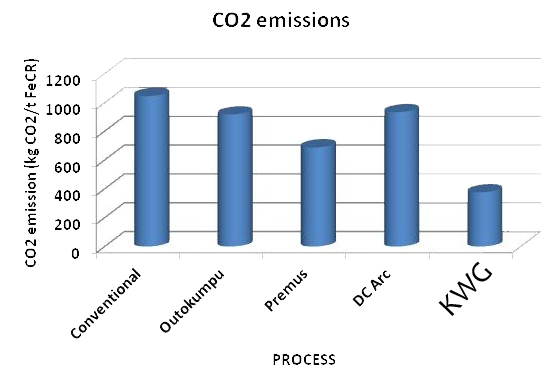

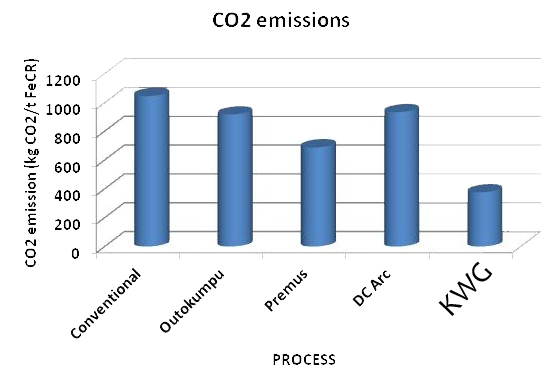

“Reducing energy consumption by alternative processing routes to produce ferrochromium alloys from chromite ore“, a “game changing” abstract, delivered at the Torstein Utigard Memorial Symposium COM in 2015, reveals elements of a techno-economic study on this revolutionary new chromite reduction process. The study identifies a reduction in overall energy consumption of 70% against conventional processing and approximately 40% lower than the current best practice.

By utilizing more natural gas than coal based energy sources, the CCC process is able to show an overall 50% reduction in greenhouse gas emissions compared with the most energy efficient current practice.

“The combinations of cheap natural gas and large quantities of high grade chromite in Northern Ontario have the potential to completely revolutionize the market for chrome units into stainless steel manufacture.”

GLENCORE XPS CONSULTING & TESTWORK SERVICES

In April of 2014, KWG acquired from Frank Winter’s interests in two international patent applications after he successfully tested his formulation for refining chromite ore into ferrochrome with natural gas at Glencore’s XPS Laboratory on project #3013814.0023.

Many years ago, Rio Algom recruited Frank Winter to turn around its under-performing investment in Atlas Steel of Welland Ontario, Canada’s last stainless steel manufacturer.

He did so, then sold the company very profitably for Rio Algom, and continued his career as a stainless steel-maker and metals trader.

This ‘direct reduction’ method makes a very pure ferrochrome, but uses 70% less energy than conventional electric-arc refining and generates virtually no greenhouse gas emissions.

Based on the methodology employed, the conclusions are that the innovative process meets all the criteria initially set:

- The need for the installation of a capital intensive smelting step is eliminated.

- An intermediate process which upgrades the ore to a saleable intermediate product is viable.

- This process has lower capital requirements than that of charge chrome smelting.

- The process effectively utilizes the substantial cost and environmental benefits of natural gas for energy.

- The need for subsidized electrical energy is eliminated.

- The operating costs for the process are significantly lower than those involving smelting as the primary method of upgrading.

A century’s supply of premium-priced ferrochrome that could be made in Canada using natural gas, requiring less energy and lowering emissions.

Exploration for diamonds resulted in the discovery of an exceedingly large chromite occurrence just below the edge of the vast, flat wetlands of the James Bay Lowlands of Northern Ontario in 2008.

Simultaneously, North America was becoming self-sufficient in oil from the fracking of shale, which also made available virtually boundless supplies of natural gas to North America’s pipeline networks. Ontario’s ‘Ring of Fire’ has the potential to become the globe’s largest and most profitable source of ferrochrome.

Ring of Fire chromite, when reduced to ferrochrome with natural gas, produces a uniquely pure product for making stainless steel.