steel would not exist

and buildings quickly crumble

steel, we cannot create lasting dreams!

by Andy Scott is clad in stainless steel

growing by 5 to 7% for 70 years

of our increasing use of metal because

it makes everything more durable

mineral claims over a 330 kilometer route

of unique high ground through

the wetlands

economic viability of mining chromite

and negative impact on the

ecologically sensitive wetlands

reducing chromite to ferrochrome alloy; natural gas

America for many decades will keep

its price low

ferrochrome at 1700 degrees in

electric arc furnaces

of natural gas reduction of chromite

"new art" and is the subject of global

patent applications

at 1300 degrees, leading to much lower

energy consumption

gas reduction replacing the existing

method is equivalent to the power

needs of a country the size of Italy

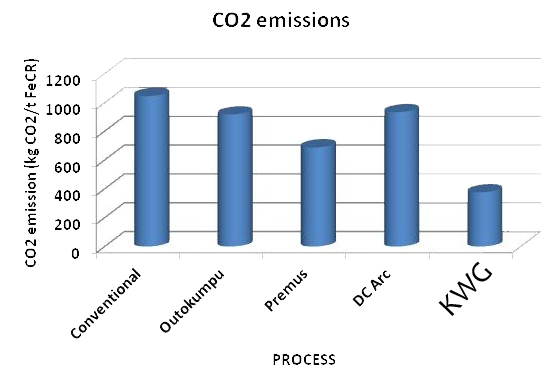

fewer greenhouse gases

revolutionize ferrochrome production

RING OF FIRE DEVELOPMENT: FIRST NATIONS AS EQUAL PARTNERS, NATURAL GAS CHROMIUM REDUCTION, RAIL AND SMALL FOOTPRINT MINE

TREATY RIGHTS: INFORMED CONSENT & SHARING THE FUTURE

In April of 2013, phase II of the Mining Act Modernization (MAM) of Bill 173, introduced a new regulatory system affecting plans and permits for early stage mineral exploration under Ontario’s Mining Act, (Click here) to promote mineral exploration and development in a manner that recognizes Aboriginal and treaty rights.

Accordingly, CCC sought the possibility of equal ownership and partnership of a proposed Ring of Fire railway through discussions with the First Nations of the area. The railway corridor would cross their traditional lands and the natural conclusion was that the First Nations should benefit in a meaningful way. CCC supports a ‘non-profit railway utility’, as an operational model, and is committed to a full resource sharing formula with First Nation ownership and partnership in the mining and reduction operations as well.

NEGOTIATION PROTOCOL RESPECTING EARLY EXPLORATION IN THE RING OF FIRE

CCC has discussed (Click here) an outline of principal terms for the possible creation of an equal partnership with the Chiefs of the Webequie and Marten Falls First Nations, through which to undertake the development and exploitation of mineral deposits in the Ring of Fire.

The parties have also agreed to discuss, at a later date, the opportunities for equity participation in CCC subsidiary Muketi Metallurgical LP, which is prosecuting two chromite-refining patent applications in Canada, India, Indonesia, Japan, Kazakhstan, South Africa, South Korea, Turkey, and USA.

CCC NATURAL GAS CHROMIUM IP DIRECT REDUCTION IN A SOLID STATE

The impact of CCC new process on future processing is therefore regarded as highly significant, with global energy reductions equivalent to the effect of completely eliminating energy demand from a country the size of Italy.

CCC’s new natural gas CHROMIUM IP, low temperature, ‘solid state’ reduction process, has enormous global competitive advantages in terms of reduced capital cost, reduced operating cost, and reduced greenhouse gas emissions.

The potential for CCC’s Chromium IP process to completely revolutionize the world’s ferrochrome industry should not be underestimated. Its impact reaches far beyond exploitation of a regional natural resource.

The patent-pending refining method yields a ferrochrome alloy (by reduction in solid-state without melting, in a reaction with natural gas).

In addition to benefits of the new reduction process itself, test work performed on Ring of Fire ores confirm that the Ring of Fire ores are generally more reducible, resulting in a 15-20% increase in unit capacity, compared to currently processed ores in other parts of the world.

Further, the chromium-iron alloy pellet product produced, can form part of the charge of conventional SAF furnaces producing ferro chrome, as batch or continuously charged components of the steel making process.

Metallised product would obtain a smelter capacity increase of 50% without any additional capital expenditure, reducing their effective capital cost from $1200 per annual ton to $800.

This dictates that a very substantial premium to the charge-chrome price may be commanded by this ferrochrome, which may also be readily purified to even higher-value ultra low-carbon ferrochrome, by argon-oxygen decarburization (AOD).

The opportunity to partner in piloting and commercializing CCC’s proprietary gas-reduction process can thus be exchanged for off-take terms with selected steel makers and AOD operators in China, Japan, Korea, and India, as they will all wish to participate in the advantages of highest purity, lowest cost and lowest emissions.

THE TORSTEIN ABSTRACT: LOWER CAPITAL COSTS & REDUCED OPERATING COSTS

“Reducing energy consumption by alternative processing routes to produce ferrochromium alloys from chromite ore“, a “game changing” abstract, delivered at the Torstein Utigard Memorial Symposium COM in 2015, reveals elements of a techno-economic study on this revolutionary new chromite reduction process. The study identifies a reduction in overall energy consumption of 70% against conventional processing and approximately 40% lower than the current best practice.

By utilizing more natural gas than coal based energy sources, the CCC process is able to show an overall 50% reduction in greenhouse gas emissions compared with the most energy efficient current practice.

“The combinations of cheap natural gas and large quantities of high grade chromite in Northern Ontario have the potential to completely revolutionize the market for chrome units into stainless steel manufacture.”

GLENCORE XPS CONSULTING & TESTWORK SERVICES

In April of 2014, CCC acquired from Frank Winter’s interests in two international patent applications after he successfully tested his formulation for refining chromite ore into ferrochrome with natural gas at Glencore’s XPS Laboratory on project #3013814.0023.

Many years ago, Rio Algom recruited Frank Winter to turn around its under-performing investment in Atlas Steel of Welland Ontario, Canada’s last stainless steel manufacturer.

He did so, then sold the company very profitably for Rio Algom, and continued his career as a stainless steel-maker and metals trader.

This ‘direct reduction’ method makes a very pure ferrochrome, but uses 70% less energy than conventional electric-arc refining and generates virtually no greenhouse gas emissions.

Based on the methodology employed, the conclusions are that the innovative process meets all the criteria initially set:

- The need for the installation of a capital intensive smelting step is eliminated.

- An intermediate process which upgrades the ore to a saleable intermediate product is viable.

- This process has lower capital requirements than that of charge chrome smelting.

- The process effectively utilizes the substantial cost and environmental benefits of natural gas for energy.

- The need for subsidized electrical energy is eliminated.

- The operating costs for the process are significantly lower than those involving smelting as the primary method of upgrading.

A century’s supply of premium-priced ferrochrome that could be made in Canada using natural gas, requiring less energy and lowering emissions.

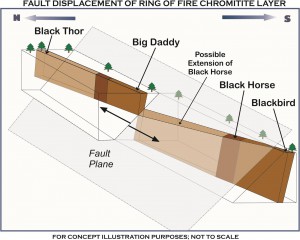

Exploration for diamonds resulted in the discovery of an exceedingly large chromite occurrence just below the edge of the vast, flat wetlands of the James Bay Lowlands of Northern Ontario in 2008.

Simultaneously, North America was becoming self-sufficient in oil from the fracking of shale, which also made available virtually boundless supplies of natural gas to North America’s pipeline networks. Ontario’s ‘Ring of Fire’ has the potential to become the globe’s largest and most profitable source of ferrochrome.

Ring of Fire chromite, when reduced to ferrochrome with natural gas, produces a uniquely pure product for making stainless steel.

SMALL MINE SITE FOOT-PRINT FOR THE BLACK HORSE DEPOSIT

CCC 3-D structural model of the 14 kilometer-long chromite horizon. From analogue and structural analysis, the depth extension of the deposit is expected to exceed its length.

Part of our mission for the development of the Ring of Fire, is to ensure that the whole project is environmentally and economically sustainable, which includes the mining operation.

A large regional project, such as the Ring of Fire, requires a truly holistic approach, where the role of each industry participant can not be oversimplified. The project components are inter-dependent. A ROF corporate project leader must oversee the chromite mining and reduction operations, the mining infrastructure corridor, and also facilitate planning and work closely with the province of Ontario and local communities to build the supporting all-weather roads. To be successful and to ensure that the whole project is environmentally, economically and socially sustainable, this momentous legacy project, must follow a multi-dimensional, comprehensive approach.

Due to the delicate environmental sensitivity in and around the Ring of Fire chromite mine area, most of the ore processing should occur 350 kilometres south, where the warmer weather and more easily contained milling operations, create favourable conditions for environmental control.

The Ring of Fire wetlands requires commitment to a very small mine ‘footprint’, where operations are mostly preformed underground.

The crushed, un-processed, run-of-mine (ROM) chromite ore, taken from underground through a relatively small mine shaft, will be directly loaded onto adjacent rail cars. There will be very little disturbance above ground.

A small mine footprint would not be possible without the “economies of scale” that come with rail transportation, enabling economic movement of large volumes of un-processed chromite ore. Even chromite concentrate requires rail transport, due to the nature of this heavy bulk commodity.

One of the most important elements of the vision is to become full and equal partners with the Webequie and Marten Falls First Nations, whose lands will be directly affected. A true resource sharing formula should include First Nation ownership and partnership in the mining, transportation and ore reduction operations. The result will produce positive financial impact for all parties of the partnership. Reducing the chromite ore in a southern location, well away from the Ring of Fire, makes sense from an environmental and economic point of view. The plants would be situated near existing infrastructure and communities, where their revenue benefits will be maximized in a Greeenstone chromite reduction location with a minimized environmental impact of the sensitive wetlands.

The possible extension of the (Click here) Black Horse chromite deposit to depth and along strike, remains to be drilled.